The next step is to foil the sheet glass in the usual fashion and place all of the parts in their final position.

The panel is then soldered on both sides as in a standard foiled work. The only difference is that the solder should be applied so as to cover all of the foil on the side of the faceted glass as shown below.

The panel is then soldered on both sides as in a standard foiled work. The only difference is that the solder should be applied so as to cover all of the foil on the side of the faceted glass as shown below.

The finished panel ready for framing is illustrated in the image below. I use brass U came 3/8 – 1/2 – 3/4″ depending on the size, weight and aesthetics of the panel simply because I like how it accents the glass. Any framing material to which you are partial ( zinc, wood etc. ) is fine as long as it will support the weight of the panel.

The finished panel ready for framing is illustrated in the image below. I use brass U came 3/8 – 1/2 – 3/4″ depending on the size, weight and aesthetics of the panel simply because I like how it accents the glass. Any framing material to which you are partial ( zinc, wood etc. ) is fine as long as it will support the weight of the panel.

There are three final issues that I would like to address in this post:

The first is the possible need for reinforcement. The best reference that I have found on this subject is a reprint ( available from the Stained Glass Association of America ) called Structure and Reinforcement in which copper foil work is discussed in considerable detail including the size of a panel where the addition of reinforcement is suggested. My only addition to their discussion is that since faceted glass may be somewhat to significantly heavier ( depending on how much is used ) than sheet glass, I suspect that reinforcement is probably appropriate for panels with a smaller surface area than that suggested in the manual. I have reinforced some of my larger panels just to be on the safe side with no scientific basis. For example, I have used brass rebar on a panel that is 20″ X 36″. In this case the rebar was run vertically anchored on the brass frame at the top and bottom of the panel and then attached to the underlying solder line at multiple sites throughout its path, a portion of which is shown below.

The rebar is hardly visible from the front and if reinforcement is considered during the design phase the lead lines can be arranged so as to minimize the visibility of the support.

The rebar is hardly visible from the front and if reinforcement is considered during the design phase the lead lines can be arranged so as to minimize the visibility of the support.

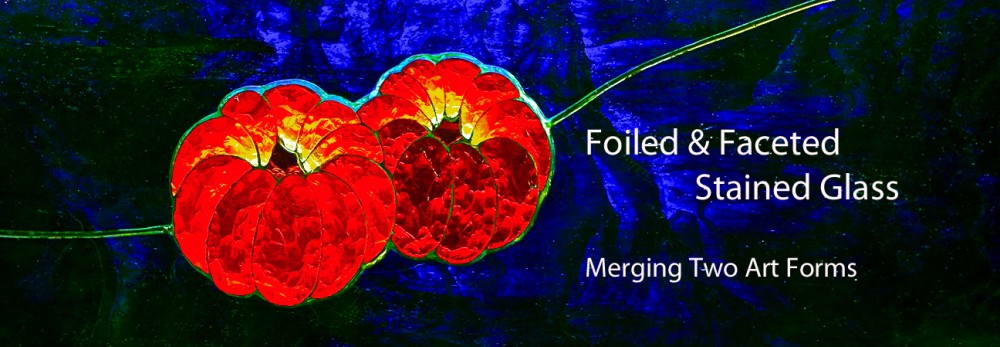

The second issue that I wanted to raise, mentioned in the About page, is the possibility of incorporating faceted glass elements such as the flowers or pumpkins that are epoxied rather than than foiled and soldered ( see posts Foil and Solder and Nautilus ) into traditional faceted glass works. This is, as with issue number three discussed below, an area for others to decide.

The third issue is posed in the form of a question: can faceted glass as described in this site be incorporated into a came ( the answer is yes, although special came was used, see reference on my home page ) rather than a foil based panel? I have never worked with came since I have always tried for the thinnest lead lines possible but with the use of epoxy ( as described in post 3.5 ) to hold faceted glass pieces together and the use of specialized a grinder head, ? the Glastar Ripple bit ?, it may be possible to create a ridge in the side of the faceted glass that might fit into the came. It should also be possible to include a piece of faceted glass into a piece of sheet glass using foil and then place the assembly into came ( this could not be weather proofed ). As with the second issue, this is a question for which I do not have an answer.